Advanced Materials Processing FAQs

Can the increased temperature variability in my annealing furnace be causing the ductility variations in my product?

It depends on the amount and location of the variability. Variability in the critical annealing parameters—temperature, dew point and atmosphere compositions—can have a dramatic impact on product quality. To help find the source of the variability, record the critical process parameters during production—larger than normal deviations in temperature can affect grain growth, hardness and ductility. Then you can correlate poor quality runs to data trends and identify what may be causing the change in properties.

Installing a process control system to monitor and control these variables can help you reduce variability. A small investment in control technology can provide a large return in reduced production costs and improved quality. Our commercial engineers and extensive experience in process controls can help you improve your process consistency and save money.

How can I increase production flexibility and ensure the quality of my annealed components?

How can I reduce my costs for Al-annealing without reducing my quality?

What causes discoloration and oxidation of stainless steels in brazing, sintering or annealing processes?

What causes stainless steel to turn green in a continuous belt furnace?

What is dezincification and how does it apply to thermal processing of brass?

What’s the best approach to select the hydrogen concentration for our nitrogen-hydrogen atmosphere for bright annealing of steels?

Is my gas purity adequate for my process?

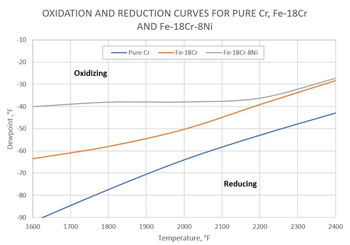

Industrial gases (such as nitrogen, hydrogen, and argon) for furnace atmospheres are characterized by their very high purity (>99.995%). Typical impurity levels are much less than 10 parts per million by volume (ppmv) oxygen and less than 3 ppmv moisture (<– 90° F dew point). This purity is typically adequate for many processes involving a wide array of materials. Some materials, though, due to their high reactivity, may require additional purification to reach even lower levels of impurity, especially with gases supplied via bulk or tube trailer supply modes. Some facilities install in-line purifiers as an added precaution against impurities picked up from the houseline. In-line purification typically involves the removal of oxygen and moisture. Sometimes with argon supply, it is necessary to remove trace nitrogen impurities. The choice of purifier is dependent on the gas and the type and amount of impurities to be removed.